GUDRUN is up and running

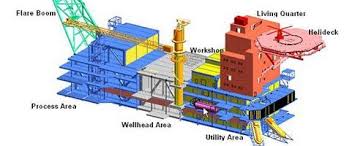

Lifetec AS worked in the Gudrun project for Aibel dealing with all noise related issues during the design phase.

We specified equipment requirements for all noisy equipment, gave recommendations on where space for acoustic insulation should be saved, predicted area noise levels and calculated ventilation noise among other tasks.

Through the project we made detail pipe noise calculations by using the project’s PDMS model and extracting the needed information which was then imported into SoundPlan. This allowed us to predict the noise contribution from every single piece of pipe in the platform. HVAC noise calculations for every room where also performed. We followed-up on all the requirements and ensure that valves and orifices plates where kept below the requirements as they are an important part for keeping pipe noise down.

The challenges during the follow-up phase were to obtain vendor calculated data for the valves. The supports for the LQ were also an issue due to the vibration transfer from the generators in the levels below.

Once Gudrun was built and installed, after a thorough follow-up in Aibel’s construction ya rd in Haugesund where the modules were assembled together, we carried out as-built noise and vibration measurements to ensure compliance with NORSOK limits and requirements.

rd in Haugesund where the modules were assembled together, we carried out as-built noise and vibration measurements to ensure compliance with NORSOK limits and requirements.

The results was one of the quietest productions platforms up to date, where nearly all process areas were below the 85 dB(A) requirements.